The following are the main advantages of the SY135C Pro excavator:

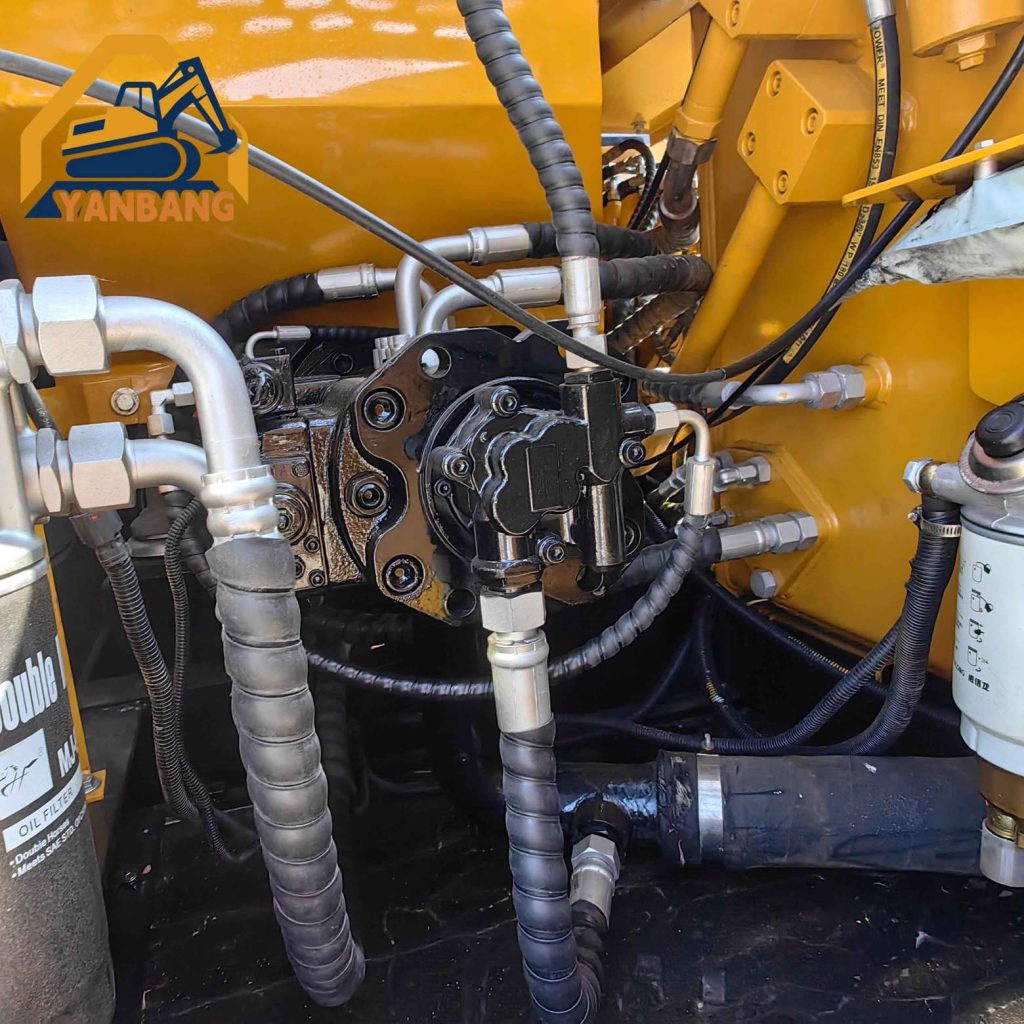

I. Excellent Fuel Economy and High-Efficiency Power This is one of the SY135C Pro’s most prominent advantages, directly reducing operating costs for users. Sany’s exclusive electronically controlled high-pressure common rail engine: This engine is either imported or independently developed by Sany. It utilizes advanced electronic control technology for more precise fuel injection and more complete combustion, providing powerful power while significantly reducing fuel consumption. New electronically controlled hydraulic system: This system utilizes a high-flow, electronically controlled negative-flow hydraulic system that intelligently adjusts the hydraulic pump’s output flow based on actual working conditions, reducing unnecessary power loss and fuel waste. Power Optimization Mode: This excavator is typically equipped with multiple operating modes (such as heavy-duty mode, standard mode, light-duty mode, and economy mode). The operator can select the most appropriate mode based on the workload, achieving the optimal balance between efficiency and fuel consumption. For example, using economy mode for light-duty operations such as land leveling can significantly save fuel.

II. Powerful and Efficient Operating Performance Powerful digging force: Optimized working device structure and hydraulic system parameters provide leading arm and bucket digging forces in its tonnage class, enabling more powerful digging and cutting, especially suitable for tough working conditions such as hard soil and gravel. Coordinated compound movements: The hydraulic system is responsive, and compound movements (such as simultaneously raising the boom and swinging) are smooth and coordinated, reducing jerking during operation, improving cycle time, and improving overall operating efficiency. Excellent swing performance: Equipped with a high-torque swing motor, it offers fast and smooth swing speeds, precise braking, and smooth, wobbling performance, which is crucial for operations requiring frequent swinging, such as loading and leveling.

III. Ultra-high reliability and durability Reinforced structural design: Major structural components (such as the lower frame, upper frame, boom, and arm) feature a reinforced design. Finite element analysis technology has been applied to strengthen high-stress concentration areas, effectively reducing the risk of cracking and extending service life. Core Component Quality Assurance: Key hydraulic components (such as the main pump, main valve, motor, and cylinder) primarily utilize high-quality components from renowned international brands (such as Kawasaki and Rexroth) or Sany’s own in-house components, guaranteeing the reliability and stability of the entire machine from the source. Advanced Anti-Corrosion Technology: The chassis and exterior components undergo rigorous rust and corrosion prevention treatments, including electrophoretic primer application, significantly enhancing corrosion resistance in harsh environments (such as coastal areas and humid areas).