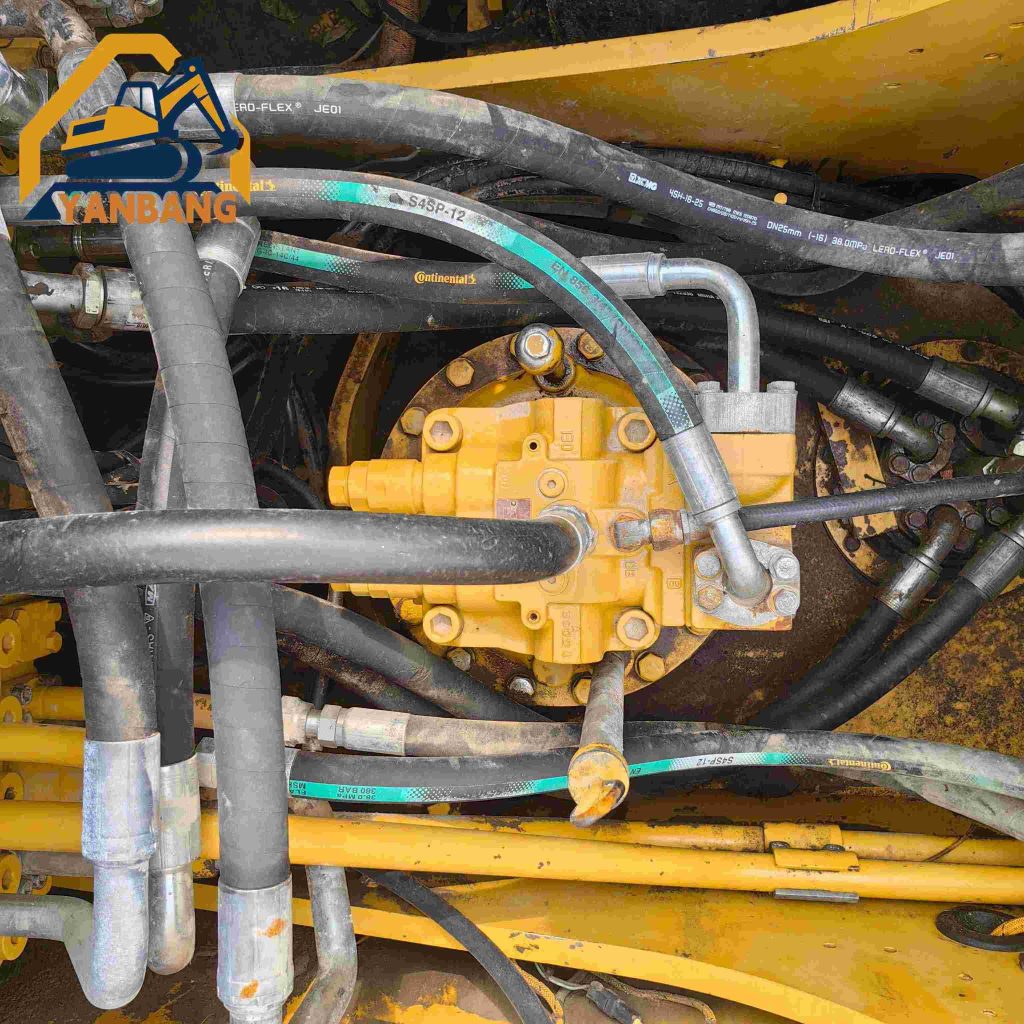

The CAT320D excavator offers powerful performance, comfortable operation, and easy maintenance, as detailed below: Excellent Power and Performance Engine: Efficient and reliable: The Cat C6.4 ACERT engine, rated at 103 kW, incorporates a series of improvements, including ACERT technology for fuel delivery, air management, and electronic control, ensuring optimal performance while meeting low-emission regulations. This engine delivers powerful power and excellent fuel efficiency. Advanced Hydraulic System: Hydraulic system pressure has been increased to 35,000 kPa, and the main pump, control valve, and hydraulic oil tank are located close together, reducing friction and pressure drop in the lines. Boom and arm regeneration circuits conserve energy during boom lowering and arm retracting operations, improving efficiency and reducing cycle time and pressure loss. Furthermore, the hydraulic cross-sensing system enables 100% engine power utilization, increasing tool speed and productivity. High Digging Force: Bucket digging force reaches 140.1 kN, and arm digging force is 106.4 kN, providing powerful digging force for a variety of challenging excavation operations. Wide Operating Range: With a maximum digging depth of 3830mm, a maximum digging height of 5610mm, and a maximum dump height of 3910mm, the machine meets the needs of various operating scenarios. Comfortable and Convenient Operation The cab is strategically designed: The radiator is located on the side of the cab on the superstructure. Outside air enters the engine compartment from the operator side, while hot air and engine noise are exhausted from the opposite side. This reduces heat and noise transmission to the operator, improving comfort. Precise Controls: The low-resistance joystick reduces operator effort and enables precise control, improving operating efficiency. Furthermore, the machine’s control system displays various operating parameters in real time, allowing the operator to easily understand the machine’s status. Low Maintenance Costs Easy Maintenance: Most common maintenance points are accessible from ground level, including the pump and filter behind the right-hand service door. The left rear service door provides easy access to the radiator, oil cooler, and other components. The radiator’s fluid reservoir and drain valve simplify maintenance, and the central grease point on the boom facilitates lubrication of hard-to-reach areas on the front linkage. Durable Components: The boom and digging arm utilize a large box-section structure and internal baffles to absorb twisting forces. These components are welded by the robot for high strength. The track rollers are sealed and dust-proof, and the grease-lubricated track chain extends the life of the undercarriage and reduces noise levels during travel.