I. Powertrain: Robust and Fuel-Efficient, Adaptable to Harsh Fuel Conditions

Equipped with a Cat C7.1 mechanical direct injection engine, rated power 109kW, high torque at low speeds, and stable power output; highly tolerant of low-quality fuels, making it more reliable in remote construction sites or scenarios with unstable fuel supplies.

Standard features include automatic engine speed control and a fuel-saving mode, saving approximately 8% fuel compared to the previous model; a variable-speed fan further reduces idling energy consumption, balancing operational efficiency and fuel economy.

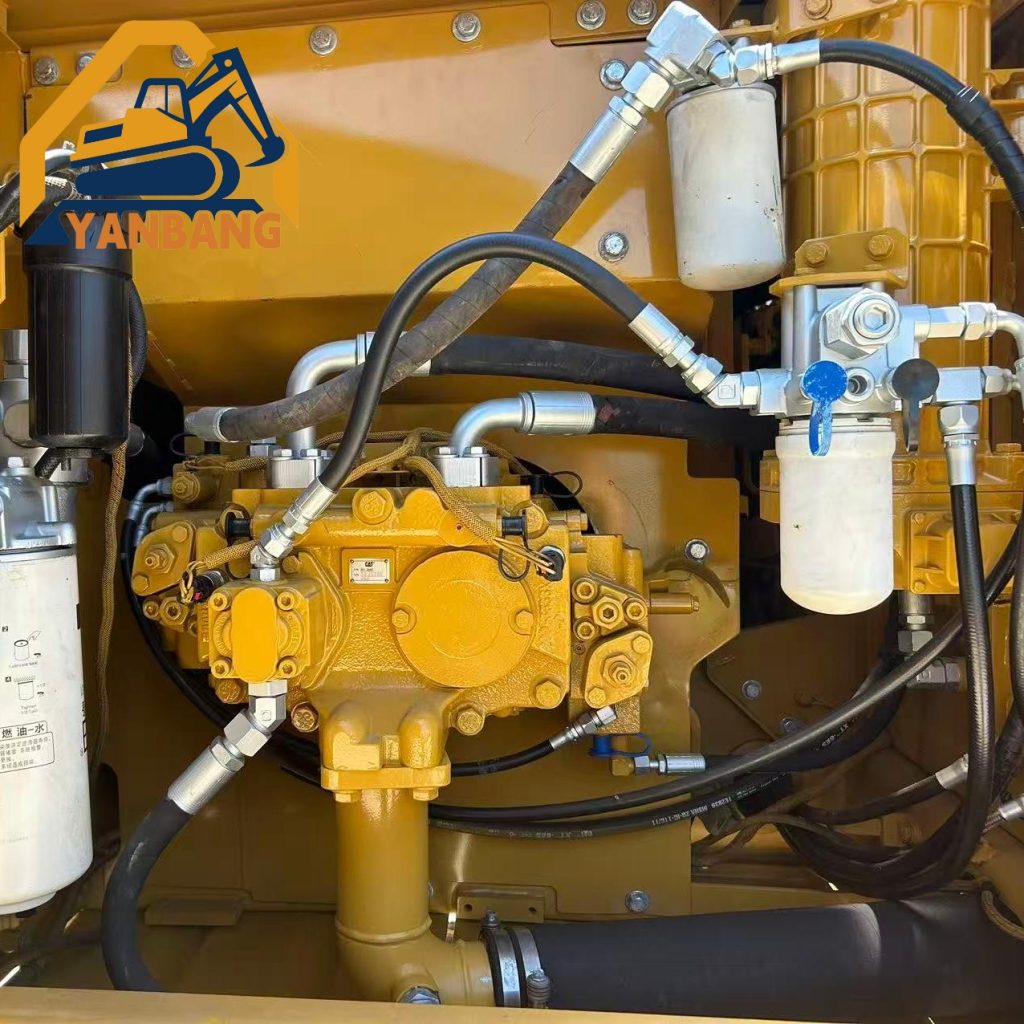

II. Hydraulic and Operational Performance: High Efficiency and Precision, Balanced Force Efficiency

The hydraulic system boasts a pressure of 35,000kPa, a dual-pump flow rate of 202L/min, a bucket digging force of 125kN, and a stick digging force of 104kN, providing excellent heavy-duty digging and lifting capabilities, suitable for earthmoving, breaking, and other working conditions.

Optimized hydraulic and engine matching, combined with a labor-saving control handle, ensures fast response, precise micro-movements, and smooth rotation and compound movements, reducing rework and improving construction efficiency.

Optional extra-long boom (up to 15.2m) and heavy-duty front linkage, adaptable to various operational needs such as deep foundation pits and slope trimming, offering strong versatility.

III. Structure and Durability: Robust and Durable, Longer Service Life

The chassis utilizes a heavy-duty track frame and reinforced track rollers and carrier rollers, providing high traction and excellent mobility on muddy and soft ground. With a total operating weight of 21.7t, it offers excellent stability.

The boom, stick, and other structural components are reinforced, with thickened treatment of key welds and stress zones, reducing the likelihood of deformation and cracking during long-term heavy-duty operation and lowering the frequency of major overhauls.

The highly efficient cooling system prevents overheating during continuous operation in high-temperature environments, making it suitable for tropical or high-load conditions.

IV. Convenient Maintenance: Reduced Downtime and Operating Costs

Routine maintenance points are centralized and can be operated from the ground. Fuel/oil filter replacement intervals are extended, with some filter elements lasting up to 500 hours, reducing maintenance frequency and downtime.

The electrical system utilizes color-coded wiring harnesses and thick braided sheaths, facilitating troubleshooting. Fewer and more concentrated lubrication points reduce maintenance workload and parts consumption.

Upgraded sealing and filtration systems reduce dust and moisture intrusion, extending the lifespan of core components and lowering long-term maintenance costs.

V. Driving and Safety: Comfortable, Efficient, and Comprehensive Protection

The cab meets ROPS standards, offering ample space and featuring an air-suspended seat, adjustable control panel, and color graphic monitor, minimizing operator fatigue. Large windows and a standard rearview camera reduce blind spots, enhancing operational safety.

Complete safety features include a hydraulic start-lock lever, ground fuel cut-off switch, and anti-slip pedals, reducing the risk of misoperation and emergencies.

Low-noise design and excellent cab sound insulation improve the driving experience during extended operation.