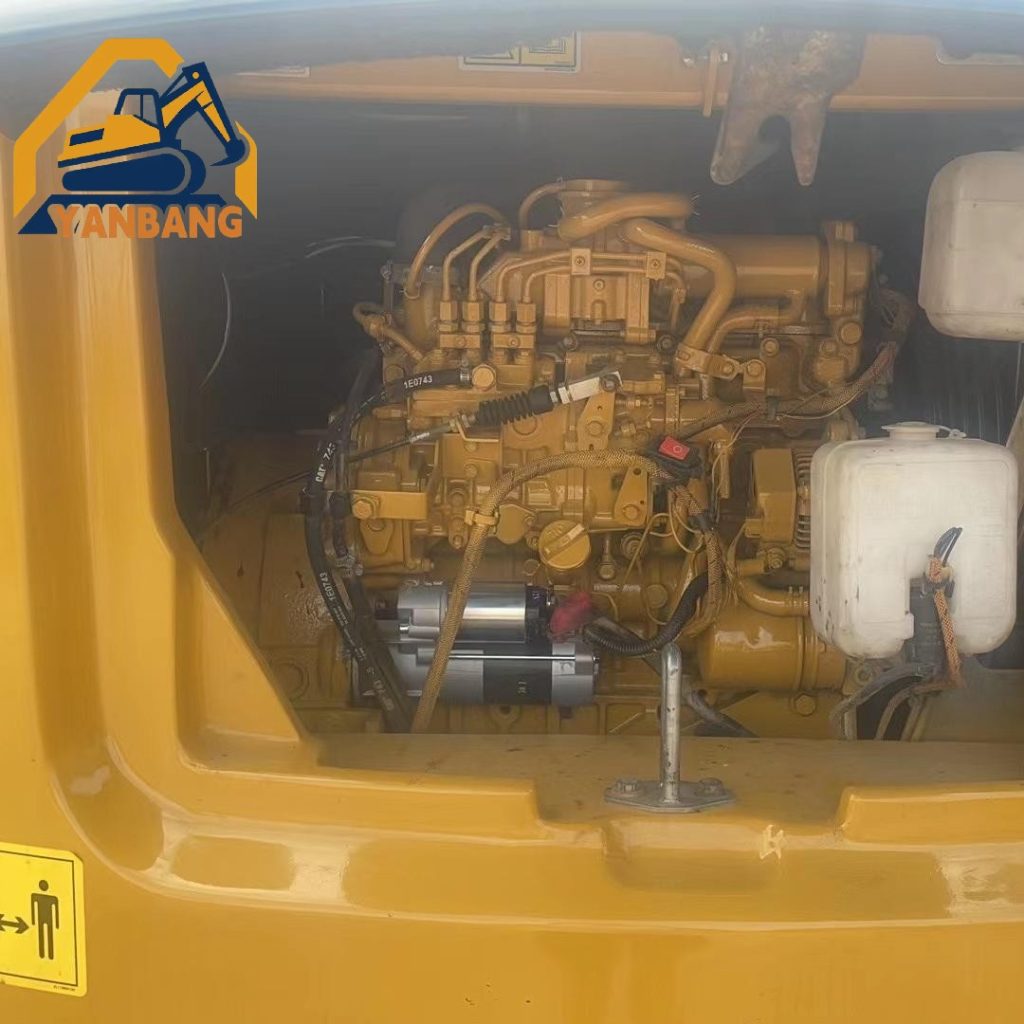

The CAT307E2 excavator offers powerful performance, comfortable operation, and easy maintenance, as detailed below: Excellent Power and Performance Energy Efficiency: Equipped with a Cat C2.6 DI Turbo turbocharged diesel engine, rated at 41.5 kW net power, turbocharging technology increases engine air intake, boosting power and torque. The engine also features dual “Standard” and “Powerful” modes, selectable with one-touch operation, for optimal fuel efficiency and productivity. An auto-idle function further reduces fuel consumption and noise. Advanced Hydraulic System: Utilizing a high-precision hydraulic system that combines the advantages of both open-center and closed-center hydraulic systems, it offers fuel efficiency, precise control, and enhanced efficiency. This system increases hydraulic pressure, boosting lifting and digging forces to 50.6 kN for bucket and 37.1 kN for arm. Compact, short hydraulic lines reduce friction and pressure loss, resulting in powerful bucket and arm digging forces and faster cycle times. Strong Adaptability: The engine can operate at altitudes up to 2,500 meters without power loss, with a cold start temperature as low as -15.7°C, making it highly adaptable to high altitudes and extremely low temperatures. Comfortable and Convenient Operation User-Friendly Cabin Design: The operator features a spacious cab, ergonomically designed low-effort controls, a standard suspension seat, and a newly designed operator environment with increased ingress and egress space. The new console features larger soft armrests and easy-to-use function buttons, while the clean, flat floor provides ample legroom for the operator. Precise Operational Control: 100% pilot-operated controls and a load-sensing hydraulic system provide responsive and precise operation. A foot switch on the control panel in the cab easily selects the maximum travel speed, enabling precise control by balancing travel speed with the torque required for steering and driving on slopes. Easy Maintenance: The “single-side maintenance” technology allows easy access to daily inspection and maintenance points through the steel hood and two large side doors. The main hydraulic valve and lines are also easily accessible through the removable floor and side panels. Additionally, the fuel and hydraulic oil level gauges are protected, and the fuel filler cap is larger, further enhancing serviceability. Rugged and Durable Structure: The boom and arm utilize an industry-unique tempering heat treatment technology. The boom features a large box-section design constructed from high-tensile-strength steel, equipped with internal baffles and an additional underbody guard. The undercarriage utilizes an X-shaped box-section body for excellent torsional resistance. The track roller frames are robust, and the upper frame utilizes an inverted “T”-shaped crossbeam made of high-strength steel, resulting in a sturdy and reliable overall structure.