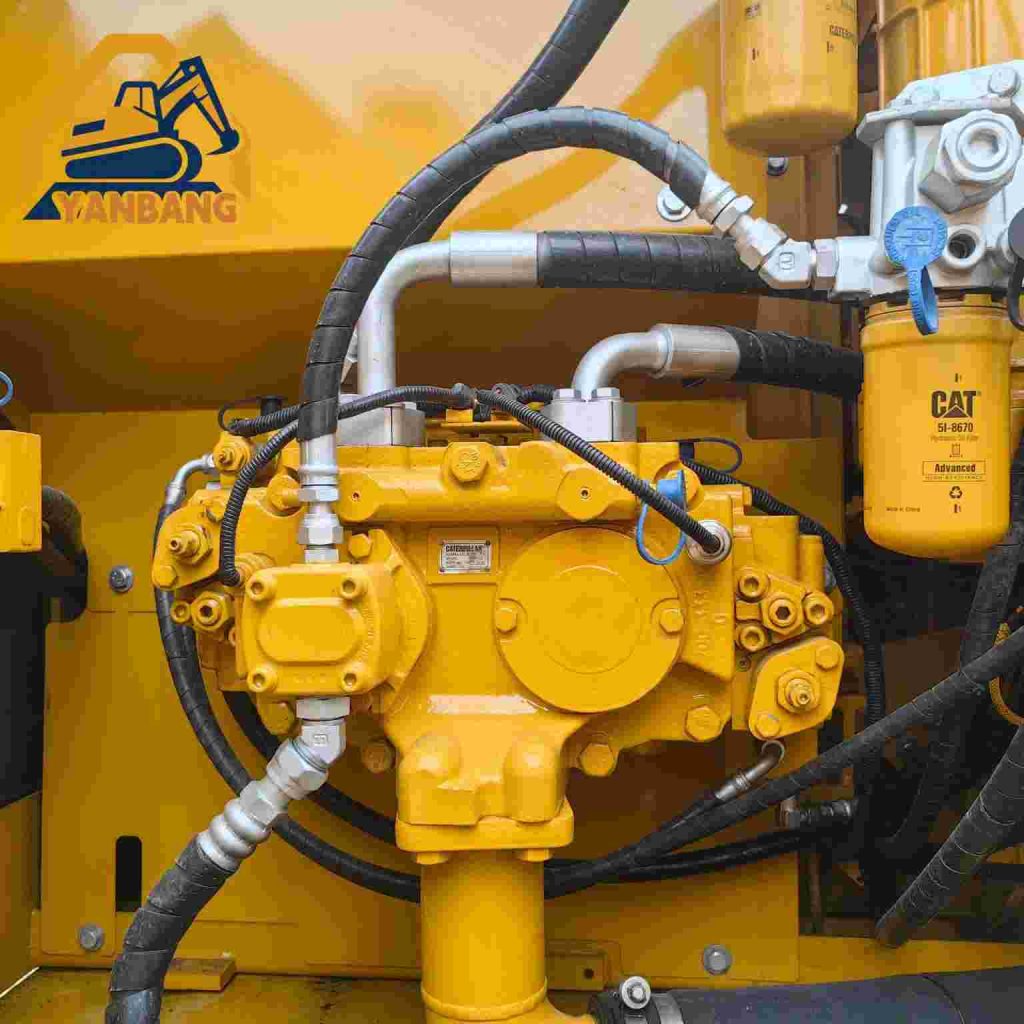

The CAT320D2 excavator offers powerful power, excellent fuel economy, comfortable operation, and easy maintenance. The advantages are as follows: Excellent Power and Performance Engine: Equipped with a powerful Cat C7.1 engine, it delivers a net power of 124 kW and offers excellent fuel compatibility, adapting to fuel quality worldwide. The engine also features technologies such as an electronic speed governor and an electric fuel pre-supply pump, enhancing reliability and maintainability. Its emissions meet US EPA Tier 2, EU Stage IIIA, and China Stage 1 emission standards. Efficient and Precise Hydraulic System: The upgraded hydraulic system features improvements to the main and pilot pumps, reducing hydraulic energy loss and improving hydraulic system efficiency. This maintains high effective hydraulic power, providing powerful and precise control and excellent bucket and arm digging forces, making it easy to handle a variety of excavation operations. Diverse Operating Modes: Multiple operating modes, including Power, Eco, and Drive, can be selected to suit different operating requirements and working conditions. This ensures the power needed for high-intensity work while reducing fuel consumption while maintaining productivity. Comfortable and Convenient Operation User-Friendly Cab: The ergonomically designed cab offers spacious interior space and a fully adjustable seat, including an optional air suspension seat with automatic weight adjustment and heated cushions, enhancing operator comfort. Furthermore, controls are strategically arranged and easily accessible, and the large color LCD monitor is easy to read in the local language for convenient operation. Excellent Visibility: Extensive glass, a sunroof, and a standard rear-mounted camera provide the operator with a comprehensive field of view, significantly enhancing operational safety. Overhead visibility is particularly excellent during truck loading operations. Low Maintenance Costs Maintenance is quick and easy: All routine maintenance can be performed from ground level. Maintenance points are centrally located, lubrication points are also concentrated and minimized, and the 500-hour fuel filter change interval (reduced to 250 hours if fuel quality is poor) reduces maintenance time and costs. Durable Components: The high-tensile-strength steel upper frame and integrated swing platform, reinforced internal baffles in the boom and arm, sealed and lubricated track rollers, carrier sprockets, and idlers, and the Cat XT™-6 ES hoses are flexible and durable. These features enhance the overall durability of the machine, reducing the likelihood of failure and repair costs.