The following are the main advantages of the SY135C excavator:

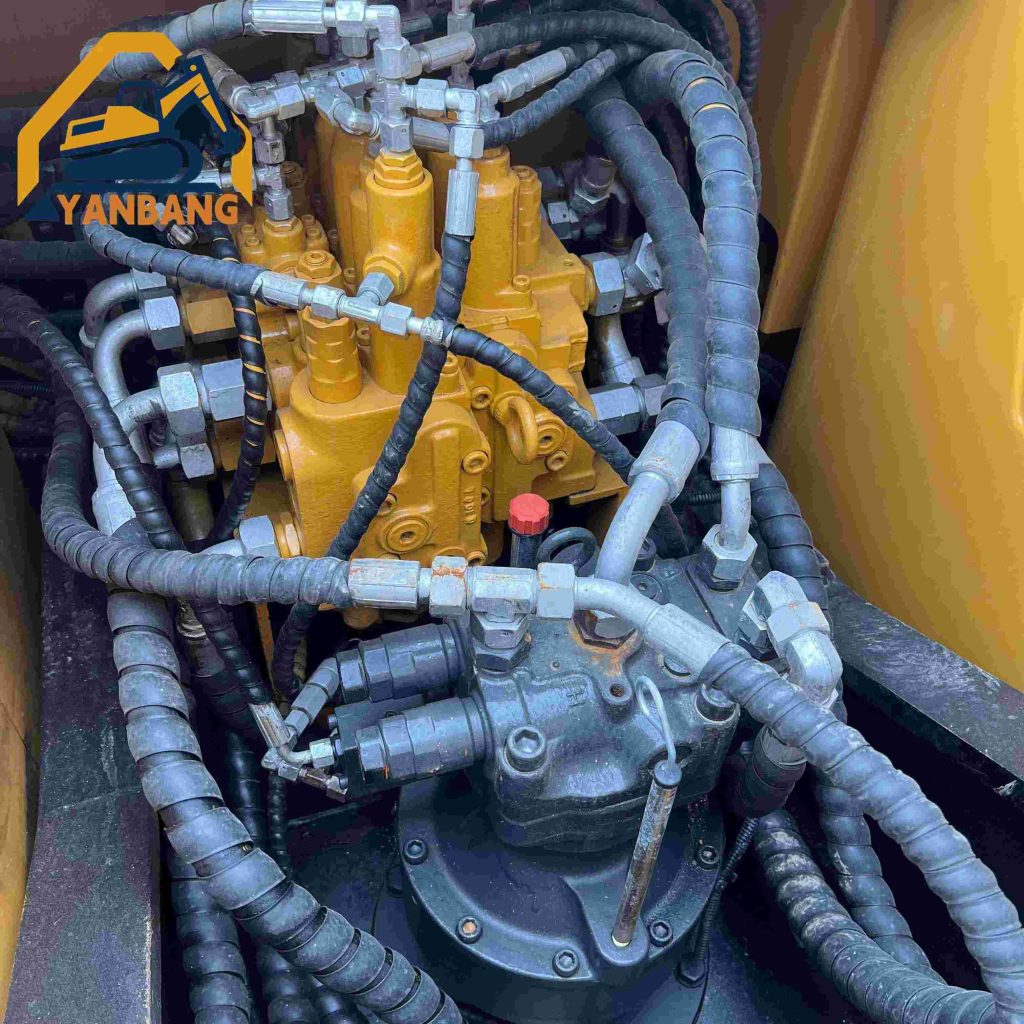

1. Excellent Core Performance Powerful and Efficient Powertrain: These excavators are typically equipped with high-pressure common-rail, electronically controlled engines from renowned brands such as Yanmar and Cummins. These engines are not only powerful enough to easily handle heavy loads, but also maximize fuel economy through precise electronic fuel injection. Equipped with an advanced main pump (hydraulic pump), they intelligently adjust output power based on load demand, reducing unnecessary energy loss and further reducing fuel consumption. Precise and Smooth Hydraulic System: The SY135C excavator utilizes a load-sensing hydraulic system (LS system). This is one of its core advantages. The system detects the operator’s operating intentions and load changes, distributing hydraulic oil flow as needed. The resulting benefits include smooth complex movements (such as simultaneous boom raising, swinging, and bucket dumping without lag), excellent micro-control performance (smooth and precise fine movements), comfortable operation, and high efficiency. Excellent Operating Capabilities: High Digging Force: The optimized arm and bucket cylinder design delivers leading digging force among machines of its size, providing greater power for digging soil and rock. High Swing Torque: The swing motor boasts ample power, enabling fast and stable swing speeds, even on slopes, for efficient loading operations. High Lifting Capacity: The stable chassis and hydraulic system provide ample lifting force, excelling in operations such as pipeline laying and heavy lifting.

II. Energy Efficiency and Environmental Protection, Low Operating Costs Ultra-low fuel consumption: One of the SY135C’s greatest selling points. Its unique combination of an electronically controlled engine, an intelligent main pump, and a load-sensing system ensures precise power matching, eliminating fuel waste. For the same workload, its fuel consumption is significantly lower than many older models and competing machines in the same class, resulting in significant long-term savings. Environmental Compliance: The engine meets China’s and global’s strictest non-road mobile machinery emission standards (such as National III and National IV), ensuring environmental protection and compatibility in a wider range of regions. Low Maintenance Cost: The reliable structure results in a relatively low failure rate. This, coupled with its high fuel efficiency, indirectly reduces maintenance frequency and costs (e.g., fewer filter changes).

III. Durability and High Reliability Reinforced Structural Design: Underframe: The underframe utilizes an X-shaped or box-type reinforced structure, offering enhanced load-bearing capacity, torsional resistance, and a longer service life. Working Attachment: Key structural components such as the boom and arm have undergone stress analysis and are reinforced in areas prone to stress concentration, ensuring they can withstand harsh operating conditions. High-Quality Components: Core hydraulic components (such as pumps, valves, and motors) and electrical components are primarily from internationally renowned brands (such as Kawasaki and Rexroth), ensuring overall stability and durability. Excellent Protection: Key components such as the radiator and hydraulic oil cooler are well protected to minimize dust and debris clogging, ensure efficient cooling, and prevent high temperatures.