The following are the main advantages of the SY95CPro excavator, which can be viewed from several perspectives:

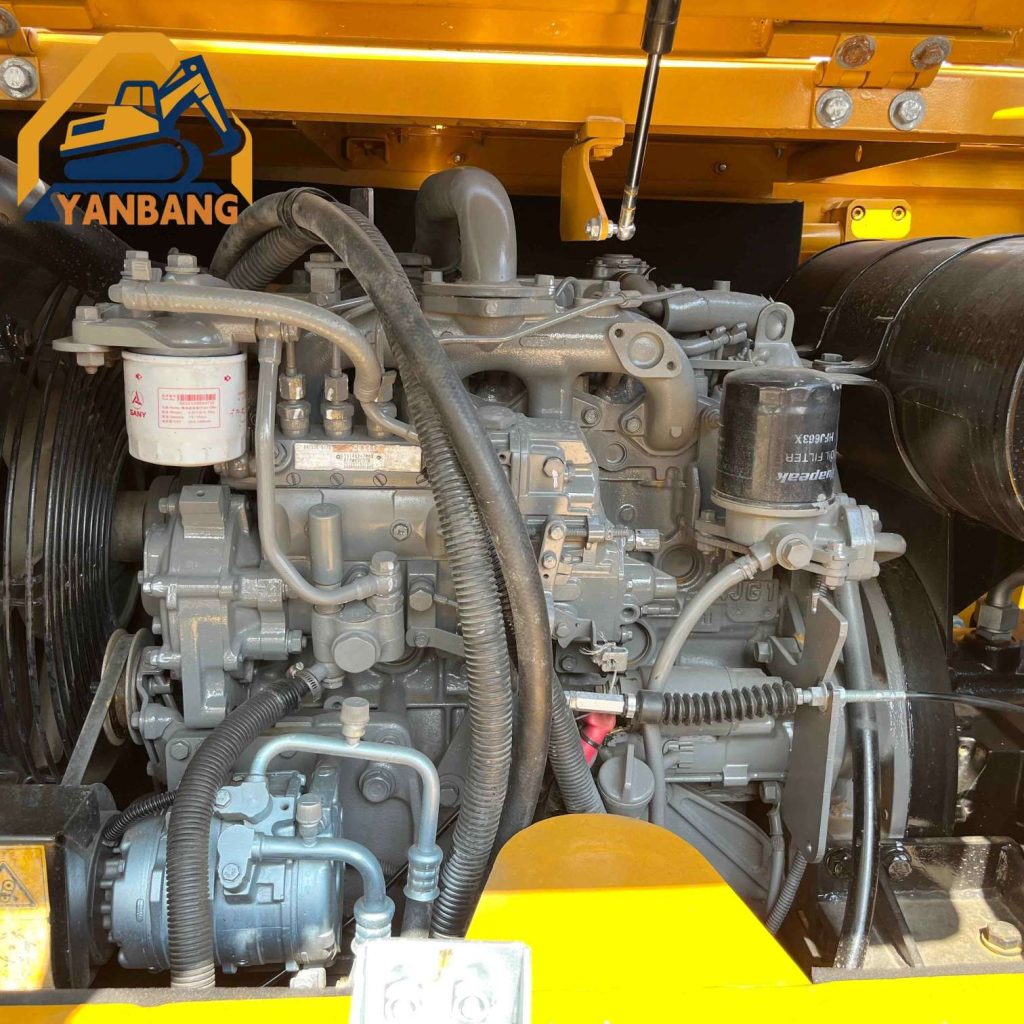

I. Core Performance Advantages Powerful and Efficient Powertrain: Imported Yanmar Engine: This is typically equipped with a well-known brand engine with low fuel consumption and high torque. It offers ample power reserves, easily handling various heavy loads and maintaining excellent performance even at higher altitudes, preventing altitude sickness. Efficient Hydraulic System: This system utilizes a positive flow control system, ensuring fast hydraulic response and precise control. The well-coordinated compound motions allow the bucket, arm, boom, and swing arm to operate smoothly and simultaneously, significantly improving operating efficiency and reducing cycle times. Excellent Fuel Economy: This is one of the SY95CPro’s core selling points. Through intelligent engine-pump-valve matching and power optimization, fuel consumption is minimized. In many operating conditions, fuel consumption outperforms competitors of the same tonnage, saving owners significant operating costs. Superior Operating Efficiency: Large Bucket Capacity: This system can be equipped with an extra-large rock bucket, enabling greater excavation and loading capacity. Powerful Digging Force: Both the arm and bucket digging forces are exceptional, making it easier to cut through hard soil and break up compacted surfaces. Fast Cycle Operation: High travel and slewing speeds enable quick transfers and rapid loading and other operations.

II. Reliability, Durability, and Ease of Maintenance Rugged and Durable Structures: The reinforced heavy-duty working attachments (boom, arm) and chassis (X-shaped underframe, heavy-duty tracks) are constructed of high-strength steel and reinforced in key areas, providing superior bending and torsion resistance and durability, making them ideal for heavy loads and harsh operating conditions. Extended Maintenance Intervals and Low Maintenance Costs: Fuel Filter: Maintenance intervals of up to 500 hours, far exceeding the typical 300 hours in the industry, reduce downtime and filter replacement costs. Hydraulic System: Hydraulic oil change intervals of up to 5,000 hours significantly reduce long-term maintenance costs and workload. Centralized Lubrication Points: Convenient daily greasing and maintenance, saving time. Convenient Daily Maintenance Design: Open the rear hood and all areas requiring daily inspection and maintenance (oil filter, diesel filter, air filter, hydraulic oil filter, coolant filler, etc.) are easily accessible. The rational layout is very convenient and reduces operator workload.

III. Operator Comfort and Intelligent Luxury and Comfortable Cabin: Spacious: The industry-leading extended cab offers ample interior space and an exceptionally wide field of vision, minimizing blind spots and enhancing safety. User-Friendly Design: A suspended seat, ergonomically designed control handles, a large color LCD display, and automatic air conditioning are all included, effectively reducing operator fatigue. Low Noise: Excellent sealing and sound insulation ensure excellent cab noise control, creating a comfortable working environment. Intelligent Electronic Control System: With multiple power modes (such as heavy-duty, standard, light-duty, and economy), the operator can select the most appropriate mode for different operating conditions, achieving the optimal balance between efficiency and fuel efficiency. Intelligent functions such as one-touch idling and automatic warm-up further help save fuel and protect the engine.